Seeking energy-efficient windows, Harvard lab finds inspiration in squid

Indoor climate control is one of the most energy-intensive things humans do. We use over a quarter of our power on heating, cooling, and lighting our homes, factories, and offices. And still that figure will jump in the coming decades as more people around the world install air conditioners for relief from rising temperatures.

To reduce emissions and mitigate the worst effects of climate change, engineers are addressing this consumption from many angles – greener appliances and lightbulbs, better insulation, new energy-saving building materials.

A team at Harvard University is looking outdoors for inspiration.

“Nature has so many beautiful technological solutions that can be utilized in a whole range of applications, even those that are totally unrelated to their biological function,” says Joanna Aizenberg, the Amy Smith Berylson Professor of Materials Science and Professor of Chemistry and Chemical Biology. “You can simply get inspired by natural designs, reformulate them for other materials and other uses, and enjoy the results. It’s out there for grabs.”

Aizenberg’s Biomimetics Lab is investigating how other members of the animal kingdom regulate their internal temperatures. Crabs, for example, can change their skin from transparent to opaque to protect themselves from the sun. Squid can control how light reflects off their skin.

“A lot of biological organisms control their ‘internal climate’ by mediating heat and light directly at their skin, which is a very energy-efficient thing to do,” says Raphael Kay, a Ph.D. student in Aizenberg’s lab. “And that begs the question: Why don’t we do this in buildings?”

With a seed grant from the Salata Institute for Climate and Sustainability, Aizenberg and Kay are exploring how to regulate indoor lighting and heating using a building’s exterior – its “skin” – starting with the windows.

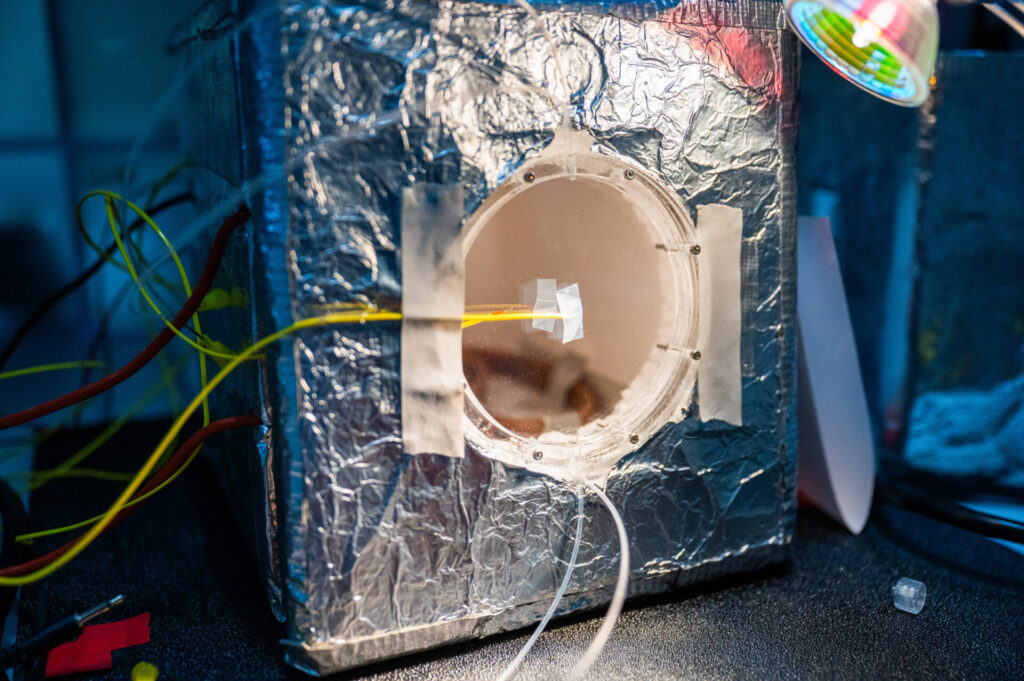

Imagine a window made of three clear sheets of plastic and glass, each containing an empty space that can be pumped full of liquid. When sunlight passes through this sandwich, a selection of fluids can be rotated in and out of the cavities to manipulate and optimize the wavelength, intensity, and dispersion as desired.

One layer holds a darkening fluid with sunlight-absorbing molecules. Think of this as a control dial for the sun’s intensity, much like a curtain: fill with fluid when you want to block light; pump it out when you want to let light through. Just as we have curtains of different thickness and colors, so various liquids can be swapped in and out to control the level of darkness.

The second layer contains a solution of infrared-absorbing molecules. Transparent to the human eye, this liquid controls the spectrum of sunlight that passes through – and thus the amount of solar heat. Withdraw the liquid when you want the sun’s heat to enter the room; inject it when you don’t.

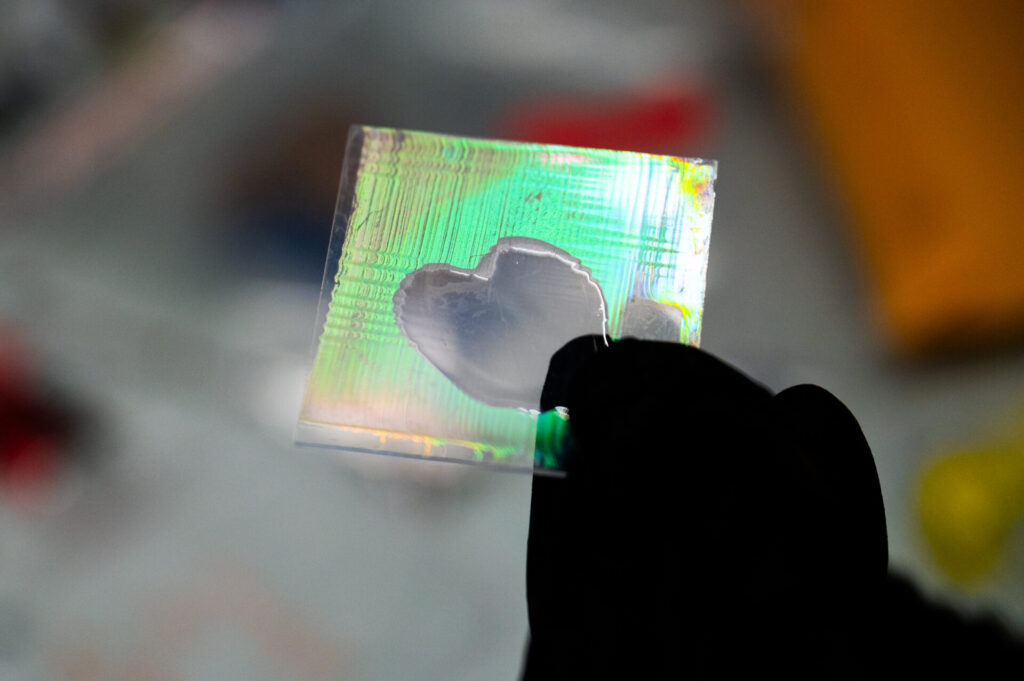

The third layer can be used like a spotlight. It is made of glass frosted with tiny scratches; when filled with a transparent liquid that has the same refractive index as the glass, those scratches become invisible and redirect light into the room, refracting wavelengths at a desired angle. This layer can be modulated for privacy control or to better tune where light lands in a room, saving energy that would have been needed for illumination.

“Take a beam of sunlight and spread it around, bring light into the far back of the room,” explains Kay, who notes that the latest iteration of the project allows this third layer to control direction on its own, without the first two layers, allowing more light to reach inside.

And it can be automated. On a cold, dark January day – when you want all the solar heat you can get, plus light – darkening fluids from the first layer will be drained and the third layer will fill with the refracting fluids. Then, on a hot July afternoon, when you want to block out the solar heat and some of the bright light, fluids in the second and first layers go to work.

“A good biological model for this is in cephalopods. Certain squid control both a pigment-based, absorption layer, and a structure-based geometrical layer underneath it,” Kay adds. “The same is true here, where liquids alone could only take us so far. It’s the combination of liquids and the solid structure that enables us to achieve universal solar configurability.”

Saving energy with everyday materials

The filters can reduce a building’s energy usage by almost 50 percent, estimates Kay, who carried out much of this research with one of Aizenberg’s former postdocs, Benjamin Hatton, now an associate professor at the University of Toronto.

While the Harvard team is designing the first prototypes to fit into existing windows, the technology can be wrapped around an entire building or be embedded in future construction materials.

If that sounds expensive, consider the supplies.

“We’re basically pushing around water inside fairly cheap plastic and glass,” Kay says.

Filling panes with liquids changes nothing about the fundamental architecture of the window.

A modern window is built of several layers of glass coated to block some sunlight. Between the layers is a dense, invisible gas like argon or krypton that stops heat from transferring through – it insulates.

Those windows conserve energy in winter, but block solar heat when it may be welcome, whereas the liquid windows channel that free energy where and when we need it.

“We’re taking the existing paradigm, and we’re just adding a couple of new cheap ingredients in strategic ways,” says Kay. “It’s a really promising scalable approach. To save energy, we can do a lot with some basic ingredients.”